GEV commences development of a pilot-scale C-H2 Ship

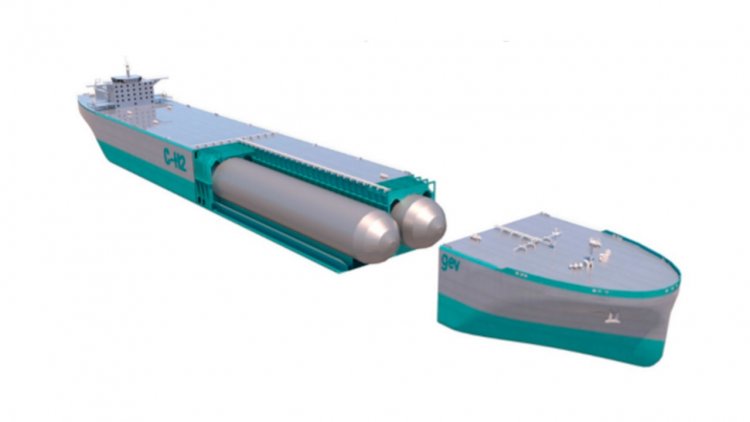

GEV has commenced the development of a pilot-scale C-H2 Ship with a cargo capacity of 430 tonnes of hydrogen.

Development program is targeting American Bureau of Shipping (ABS) Approval in Principle (AIP) in Q3 2021 and Full Class Approvals late in 2022.

The 430-tonne ship specification will be a scaled version of the 2,000-tonne C-H2 ship (that received AIP in March 2021) and benefits from the engineering and HAZID studies already completed.

The downstream market application for pilot scale volumes of green hydrogen will include customers to inject such volumes of green hydrogen into existing natural gas pipelines (i.e., blending). Regions with aspirations to develop a hydrogen economy are likely to turn to grid injection as a means of cultivating a market and stimulating investment into supply.

Martin Carolan, Managing Director and CEO commented:

“GEV’s design and development strategy for the 2,000-tonne ship proved that large commercial scale C-H2 ships are possible and paved the way for the development of a pilot-scale version. The 430-tonne ship is an ideal size to meet the needs of the current emerging H2 marine transportation industry and will ensure we establish ourselves in the marine transportation of green hydrogen.

Extensive marketing of our C-H2 solution has provided valuable insights into both the scale of supply and demand for green hydrogen in the mid-late 2020’s. A pilot-scale ship will be complementary to partner discussions and GEV’s target to develop a fully integrated green hydrogen supply chain from Northern Australia. This includes GEV’s own renewable energy project to produce green hydrogen based on a specific customer use case, delivered with our own C-H2 ships.

Blending is an attractive source of near-term demand for hydrogen at low blend volumes due to low incremental costs and aligns with C-H2’s modular approach for production scale-up. The scale of a 430t ship can alleviate the additional infrastructure requirements that a liquefaction or ammonia project will require to deliver a pure hydrogen gas to the end user. Regions with aspirations to develop a low-carbon hydrogen economy are likely to turn to grid injection as a means of cultivating a market and stimulating investment into supply.”

GEV has assembled a team with a successful track record of achieving AIP and the expertise to take the C-H2 ship through to Full Class Approvals with ABS by the end of 2022. More details will be provided on the key milestones in the coming quarters.”

Strategical reasons to move forward with a pilot-scale C-H2 ship, include:

- GEV’s analysis of the near-term supply and demand for green hydrogen in the 2025-2030 timeframe, making this a world first for the marine transport of green hydrogen at scale.

- The 430-tonne containment system fits within a Handymax sized vessel envelope which reduces the development time and cost, maintains a practical ship draft of 9 metres, whilst also optimising the scale of the ship to match hydrogen production volumes.

- A smaller capacity ship aligns with opportunities under review for European and Asia Pacific demand centres for downstream applications such as grid injection (blending) and fuel cells.

- Aligns with GEV’s own renewable energy and hydrogen export project of up to 1.5 GW of renewable energy, matched with a scaled production and delivery of green hydrogen from Northern Australia to Asia.

The key specifications of the 430 tonneC-H2 Ship

The proprietary design for the containment system is made up of two large circular 12m diameter tanks, contained within the hull of the ship, that will store ambient temperature hydrogen at an operating pressure of 250 bar and will have a combined containment capacity of 430 tonnes of hydrogen.

One of the key considerations in designing a steel tank for storing hydrogen, is that the hydrogen molecule is so small it can enter the steel’s molecular structure and over time can cause the steel to suffer from embrittlement. Embrittlement is managed in our design by providing a liner such as stainless steel that prevents the steel structure from becoming damaged by the hydrogen.

The cargo tanks will be constructed with a liner of stainless steel surrounded by multiple high-strength steel layers. This layered approach has several advantages:

• The individual layers are capable of being economically produced with the appropriate mechanical properties (the wall thickness of a single layer tank of this dimension would be outside the normal range of steel plate production).

• Each layer can be formed easily to shape at the shipyard.

• The inner liner protects against hydrogen embrittlement.

• Should a fatigue crack initiate it cannot grow beyond the layer in which it originated.

These features create a large tank that is economic to produce and has large safety margins.

Propulsion will be electric drive supported by the rapid advancements in hydrogen blended generation and hydrogen fuel cells. GEV intends to fuel the ship with hydrogen from the storage tanks, providing a ‘zero-carbon’ shipping solution. The C-H2 ship will be equipped with dynamic positioning for rapid connect and disconnect of near-shore buoys.