Opinion: Decarbonisation of fleets is crucial, and digitalisation is the way to achieve it

The modernisation of shipping starts with the introduction of digital technologies. This approach will help to avoid environmental challenges in the future and, as a result, save money for shipping companies, insists DeepSea's Commercial Director, Angus Whiston, in an exclusive interview with Seawanderer.

- The decarbonisation target that the IMO has set is ambitious for many reasons. How, do you think, will the sector realistically achieve these goals by 2050?

- I think there is only one honest answer that anyone can give about this, which is that we simply do not know. What’s helpful at the moment, though, is to explore the methods currently available to shipping companies which will allow them to meet these targets.

Broadly speaking, there are three approaches to consider here. One of them is alternative fuels, which, of course, are immensely expensive at the moment. The feasibility of the supply chain is still uncertain, and a series of other challenges still exists as we work to determine which fuel is most viable.

There is also the LNG route to consider. In theory, this is a worthwhile option. However, with the recent IPCC report pointing to concerns over methane emissions resulting from LNG’s production and use, there are questions as to whether this approach could even be considered a facilitator of decarbonisation. Furthermore, some major shipping corporations such as Maersk and IKEA have said that LNG may not be the route to decarbonisation. In fact, it was recently described as “borderline greenwashing” in a recent Lloyd’s List podcast. These are the two approaches that are most often discussed - alternative fuels and LNG.

DeepSea's Commercial Director, Angus Whiston

Another key approach - and one that is complementary to those I’ve mentioned - is improving vessel energy efficiency. This is an immediate focus of the IMO and critical to securing emissions reductions from available technological and operational solutions. While shipping companies consider all potential long term approaches to decarbonisation, they should invest in energy efficiency right now. This approach is not only an incredibly low risk option, but it is also one that will never become outdated or outpaced by potential new approaches to decarbonisation. Energy efficiency already is - and will continue to be - an essential initiative to complement existing and new decarbonisation strategies. Indeed, the long term returns on investment of energy efficiency technologies are guaranteed, and they can be quite substantial (even a 10-15 per cent saving on OPEX).

- To achieve such a goal, we need to clearly understand where we are now. For example, we need to have reliable information about the amount of emissions ships are emitting at the moment. In your opinion, how accurate is this measured in the maritime industry at the moment?

- From our perspective, shipping companies can’t improve something that they can’t accurately measure. That’s why measuring is such an important issue. A majority of the shipping industry is still measuring or reporting fuel consumption through noon reports - with all of the errors that come with this method of reporting: from manual errors, to overall reporting errors - both unintentional or otherwise. How do you solve this problem?

We believe that improving methods of measurement is the first step in improving accuracy in the use of noon reports. We’ve launched a product called Cassandra Light, which uses AI to build performance models for each individual vessel. We can use this information to validate reported fuel consumption. Improving the accuracy of measurement is our main objective whenever taking on a new company as a client - and AI is the key to achieving that.

Another interesting question is what to do with that accurate information once obtained. DeepSea’s approach is to build models, so that we can understand the behaviour of vessels under a variety of conditions. It is only when you understand the vessels, that you can optimise them. At DeepSea, we believe that a lack of information is the biggest polluter.

- Today, digital technologies are one of the most progressive methods of decarbonisation. But on the other hand, the use of AI technologies has been directly associated with new risks. For example, there has been some concern around how this technology is a potential cybersecurity threat. How justified are such concerns?

- There are two key elements to this. The biggest problem we’ve faced with our work within the artificial intelligence space has been a lack of data maturity. The digitalisation of a company can be a slow process without adequate investment in its transformation. Engineers, who are often our first point of contact when approaching potential clients, quite rightly question everything they come across. They are taught to work out, in very high pressure situations, what’s going right, and how to maintain success. Conversely, they are also taught to ascertain what’s going wrong, and how to fix it. With artificial intelligence still quite a new concept and technology, it’s no surprise that these professionals are somewhat skeptical.

An AI approach is not a plug-and-play solution. It takes time to gain the data and insight required to implement new, more efficient systems and processes. What we try to do is build trust by interpreting our findings and presenting them to clients in a way that communicates outcomes of our AI products in the clearest possible way. For example, we’d generate a vessel performance curve with the insight gained through AI.

AI may seem mysterious, but we focus on proving that it isn't. By being completely transparent, and providing additional educational support to our customers’ teams, we aim to prove the value of our services and increase trust in the technology.

When it comes to cybersecurity there is nothing about our approach - or AI in general - that puts our customers at any additional risk. When handling the data that our clients have given us access to, there are a number of processes we follow, and strict measures we’ve put in place, to ensure its security. DeepSea Technologies is ISO compliant, which involves the anonymisation of all data where possible, to ensure there is no connection between the insights we gather, and the clients that have paid for them. Vessel data we collect is also handled through a read-only interface, ensuring that nothing sensitive can be copied and distributed elsewhere.

Overall, if you take the right approach it’s a very low risk in terms of cybersecurity. In modern times, data is an essential part of vessel operations - needed not only for performance optimisation and risk analysis, but also regulatory reasons, too. It’s no longer avoidable. If you take the right approach, AI carries a very low cybersecurity risk. My advice to business owners is to take this new digital era seriously. Big data and artificial intelligence aren’t going anywhere, and are quickly becoming essential to the success of companies across the globe.

- Another difficult issue related to the launch of new technologies is financial costs. If we compare the cost of digitalisation with other methods of decarbonisation, which method comes out on top?

- Optimisation through digitalization is something that everybody should be doing right now. The alternatives are not alternatives - they are additions, complementary to efforts already in action. Importantly this approach to decarbonisation - energy efficiency/digitalisation/optimisation approach - is low hanging fruit. It’s very low cost, comparatively, and requires almost no CapEx investment. The results of this approach can be dramatic, and many expensive retrofits pail in comparison.

Committing to a digitalised future is also very low-risk. These changes need to, and will, happen - and will be beneficial across the board. For example, if you compare digitalisation to the LNG approach, there are many more questions in terms of longevity. “How long are these assets going to be valuable for?”, “How will the supply chain work?”, etc. Digitalisation is the closest to a sure thing that we’ve got in the current decarbonisation landscape - it’s a no brainer to me.

- What other barriers and challenges do you see for adoption of this type of technology?

- DeepSea is pleased to be in a position where technology, for the first time, is no longer really a barrier. We’ve just closed our latest funding round with Nabtesco as the lead investor. This involved a rigorous due diligence process, whereby our technology was tried and tested, and our claims validated. We’re happy to report that findings were conclusive, and our partners were very impressed. Having passed those tests, I can proudly declare that in terms of this technology and DeepSea’s objectives, technology, at least, is no longer a barrier.

That’s not to say that there are no barriers at all. At DeepSea, I’d say that our greatest barrier is securing buy-in from shipping companies - our clients. For many years, these companies have been fed false narratives about what this technology can do, which has tarnished its reputation. Despite now having provable returns, companies can still be reluctant to commit to these kinds of projects. What’s encouraging, though, is that once we’ve worked with and proven ourselves to a client, and they have experienced the value our services can offer, this apprehension is no longer a factor.

A key message I’d like to communicate to members of the industry, of any size or kind, is that vessel optimisation is not a transaction - it’s a service, enhanced by the relationship you have with your supplier. Here at DeepSea, we aim to support these companies in order to guide them, individually, but also the industry as a whole towards a greener and more transparent future.

- The use of weather forecasts could be classified as a rather unconventional method of decarbonisation. Please describe in more detail (using specific examples) how it works.

- This question is interesting, because I would say that the use of weather forecasting is pretty much the oldest method of optimisation in shipping. There was a time when you’d have someone on the front of the boat or oracle, notifying crew of an approaching storm. The captain would then move around the storm - it’s as old as shipping itself. This logic can be applied just as effectively today - if you avoid the storm you save a huge amount of fuel and manpower.

In today's landscape, where the IMO’s emissions reduction targets are set at one per cent a year for the next couple of years, this is an indication of just how difficult it is to bring about these changes within the shipping industry. I think we can be much smarter, and focus on the effect that smaller changes can have on our greater goals.

Utilising technology of today, tailoring the route and the speed to the specific performance profile of vessel is new. The weather forecast is obviously a key part of that.

For example, a vessel that is quite highly fouled will be more affected by currents, both positively and negatively. As a result, taking these small differences in every vessel into account is critical to achieving those savings.

Through the application of artificial intelligence, we build an understanding of each individual vessel, which is then used to generate our performance models. By implementing changes that these performance models highlight as necessary, massive savings can be unlocked - up to 8% in fuel savings according to our recent case studies. These savings result from a variety of measures - one of which being performance routing.

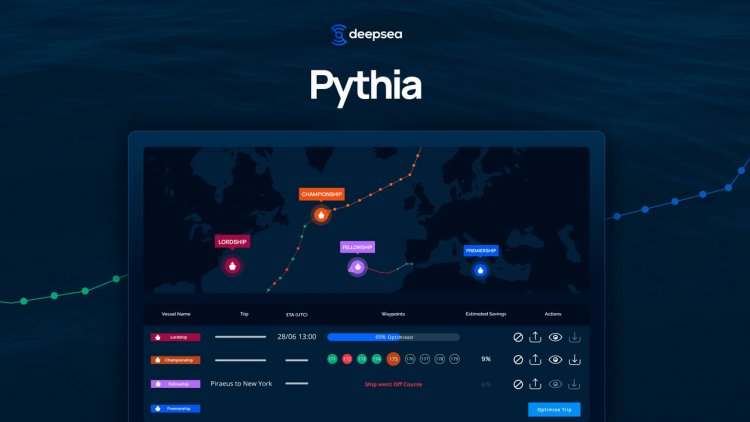

- Your products, Cassandra and Pythia, have been installed on a number of ships. Based on the insights that you've been able to extract over time, what are the most common issues that reduce the efficiency of ships?

- The key point here is to take an individual approach that focuses on understanding each vessel. Once we understand the vessel, the solutions come. They are not necessarily complicated solutions, they can be very simple, but they are specific to every vessel.

A good example is a ducted propeller system. It feels like fitting it would be great, but in fact, the performance of a vessel with a ducted propeller can be worse at certain speed rates under certain conditions. As a result, you have to understand the vessel to understand the impact of the retrofit. That is the key to the actual optimization that we are looking for.

by Iryna Umanets