Successful demonstration of new cargo hold monitoring system

The new system is a comprehensive management system for reducing the risk of damage to cargo.

On December 5, Nippon Yusen Kabushiki Kaisha (NYK), NYK Bulk & Projects Carriers Ltd. (NBP), and MTI Co., Ltd. (MTI) completed a 35-day experiment using IoT sensors to measure the holds of dry bulk vessels, effectively confirming the effectiveness of the system in actual voyages.

The quality of the hold environment during the voyage is an important factor in maintaining the quality of marine transport on dry bulk vessels. At present, it is common for crew members to periodically enter the hold to visually check the condition of the cargo, but there are issues such as the risk of crew members overlooking abnormalities and the inability to enter the hold to conduct inspections during rough sea conditions.

To solve these problems, technologies for monitoring the hold environment using equipment that requires wired communications and a power supply have been developed, but their use has been limited because they require construction work to be done on the ship and large investments.

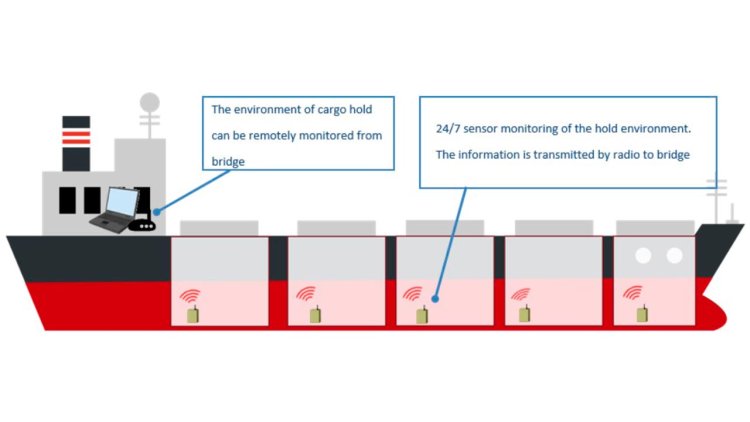

The three companies have therefore developed a new system that does not require any construction work on the vessel. The new system is a comprehensive management system for reducing the risk of damage to cargo. It features 24-hour remote monitoring and data collection of the holds of dry bulk vessels, analyses of past data, and visualization of cargo-damage risks based on predictions of future conditions.

In dry bulk vessels, it is difficult to supply power to wireless communication and sensor parts from the hold. IoT sensors using LPWA wireless communication technology can be used to monitor the transport environment, such as temperature and humidity in the hold, and the sensors can be remotely monitored in real time from the ship's bridge during the voyage. In addition, the system has a function to notify the crew with alarms or other means if it observes data that could cause damage to the cargo.

Furthermore, sensors monitoring temperature and humidity can be replaced to monitor acceleration, water leakage, illumination, CO (carbon monoxide), etc. By accumulating this data, it will be possible to predict conditions based on past data analysis, which is expected to further improve the quality of transport.

The experiment conducted this time was an operational experiment of 24-hour remote monitoring and data collection in the hold. With the cooperation of Nippon Steel Corporation, temperature and humidity sensors were installed in the holds of Global Mirai, a steel carrier bound for Mexico, and data was collected. The data was then transmitted to the ship's bridge, and the status of the holds was monitored from a dedicated PC.